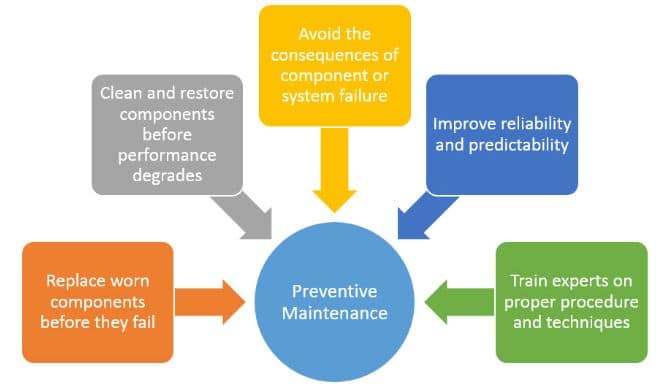

The advantages of preventive maintenance software, a typical component of CMMS software, offer you a broad scope of capabilities and various benefits.

Predominantly, it helps you survey and assess resources to make sure that they are working at peak performance for an organization.

CMMS has the function of acting as a “decision support apparatus” for maintenance. It helps you promote preventive maintenance measures in your logistics business to guide users from entirely depending on reactive maintenance schedules.

Preventive maintenance software gives your organization various points of interest, including peace of mind, complete organization of your logistics schedule, and an ideal work environment.

They likewise increase your bottom line by diminishing costs and boosting revenue.

Benefits Of Using Preventive Maintenance Software For Your Logistics Business

The following are some of the benefits of utilizing preventive maintenance software for your logistics business:

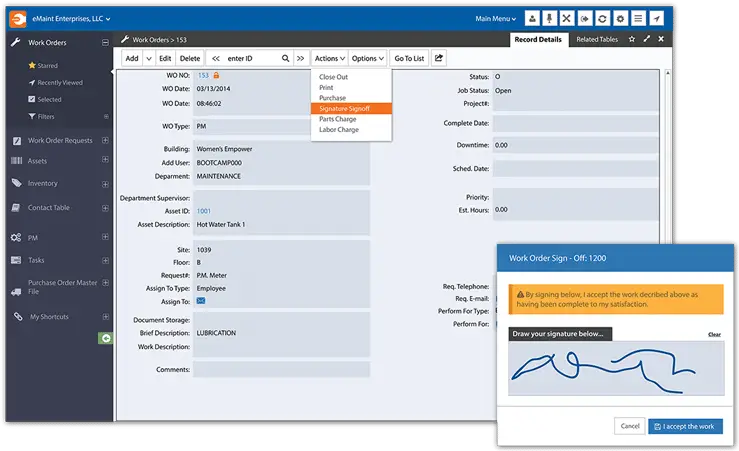

Work Ordering

Work order management software can do the entire job of streamlining your work request order processes, but when you need something more vigorous, CMMS has your back.

CMMS preventive tools make sure that planning and finishing resource maintenance gets completed effectively and quickly. These frameworks aid your organization to visualize and automate work order processes and handle maintenance tracking through the entire process.

They help the administration track maintenance history and other activities and delegate assignments to workers. This improves the intra-communication and reduces the requirement for micromanagement of professionals.

Most preventive maintenance software gives role-based access to work orders, permitting only approved users to mark them as complete. This is a crucial process that makes the logistics workflow swifter.

Building Reports

Over the long run, your organization will need reports that demonstrate when and how maintenance activities were done and how they were accomplished for individual resources.

Itemized reports help provide you with information regarding preventive maintenance exercises and demonstrate a broader perspective on how your logistics business is being run.

Exhaustive CMMS tools can help supervisors set up various types of reports. Contingent upon the system, they can utilize built-in KPIs such as serial numbers, model numbers, or information qualifiers like producers, warranties, and purchase information.

This is a significant advantage of preventive maintenance software— you can assess the maintenance done against the particular warranties, which offer some value for resources.

This implies that if something is under warranty, the support staff and every other person will know about it immediately — it has a significant effect on handling upkeep.

Greater Efficiency, Better Outcomes

Maintaining a transportation network without any kind of problems isn’t simple, particularly when you have numerous resources on the move. This requires a ton of preventive maintenance planning.

Utilizing preventive maintenance software, your organization will have the ability to follow and investigate all your fleet’s use, review prerequisites, and expenses.

Assigning Work

For organizations with more significant staff or even an office with more than three workers, assigning work is a substantial part of the everyday process.

There are timetables to plan and correspondence that needs to occur between the technician and the worker who initiated a work order. With preventive maintenance software, workers can be assigned various tasks effortlessly.

Portable access is a vital feature of CMMS for allowing easy work delegation. Any kind of delays that happen when clients need to hold back on receiving work orders or parts can be moderated by permitting access to the system from a massive range of devices.

Building A Consistent Routine

Most of the gear has a specific timetable to monitor when maintenance executives need to service them. Whether it’s a vehicle, a mechanical assembly on a work floor, or some other business resource, maintenance will have to be consistent.

Preventive maintenance software enables you to make these processes transparent, to show they are being done reliably and all around across the business footprint.

With CMMS in place, nothing gets lost in the noise — everything gets completed within the stipulated timeline to ensure resources are serviced and maintained to the same standard.

You can take the preventive maintenance software a notch up and order it to auto-plan predictive upkeep checks at the assigned time intervals.

You can even personalize these timetables by hardware priority, maintenance protocols, or production cycles. This guarantees reliable screening of all resources and prevents human blunders.

Resource Monitoring

Resources are the core of your organization’s functional capacity, and CMMS software offers exhaustive resource management abilities.

Resource management modules incorporate resource monitoring and tracking. This ranges from live video streams of physical resources to comprehensive GPS fleet tracking.

ALM is an acronym for Asset Lifecycle Monitoring, a prevention maintenance feature that permits you to track resource usage, performance, and expenses to more readily optimize resource performance.

Better Safety And Regulatory Compliance

Your resources aren’t the only things that will thank you for using preventive maintenance, so will your legal team! The software helps you to maintain regulatory compliance and makes your logistics facility safe and secure.

The software tracks every type of maintenance and saves a comprehensive document for auditing purposes.

If a piece of hardware falls flat despite being appropriately maintained, regulatory organizations have no way of knowing this without these documents.

Besides, you won’t need to go burrow through your file cabinet to access this data; creating reports for reviews and assessments is simple with preventive maintenance software.

Your staff will likewise benefit from the use of CMMS. The board can effortlessly track health and security data utilizing CMMS, decreasing administrative work that should be filled out or stored.

CMMS can also keep your staff more secure by organizing training exercises, storing training documents, and guaranteeing no holes in safety norms.

Fewer Disruptions To The Workday

One incredible advantage of having CMMS software is the decrease in the number of interruptions to the workday. This will permit all the representatives of a department to keep up their flow, ensuring extreme productivity.

The value of a streamlined workday is irrefutable regarding both worker satisfaction and profitability.

Conclusion

Preventive maintenance features of CMMS are precious. Through preventative maintenance standards, logistics organizations can be confident that they are competing well in industries that rely on having the best and up to date infrastructure set up.