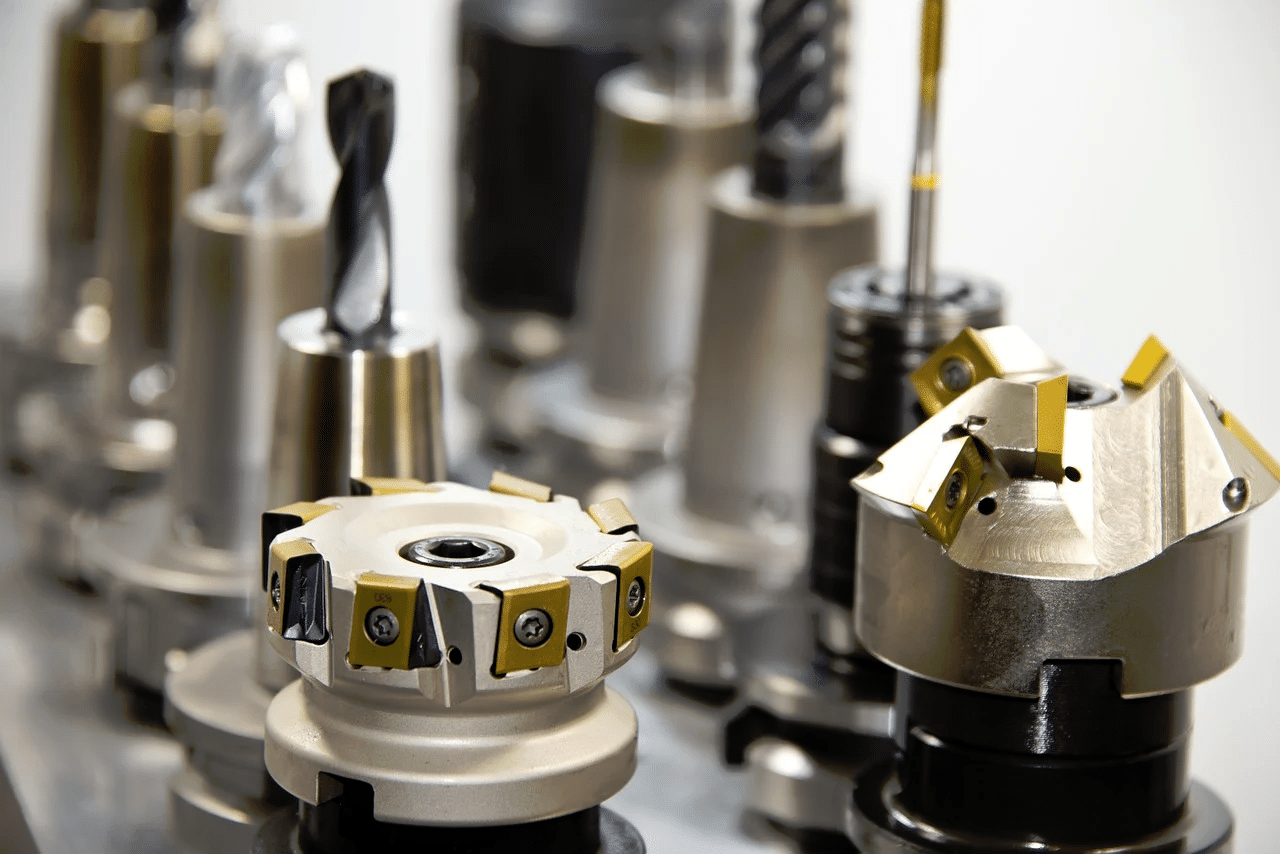

CNC machinery is often talked about as a homogenous category of equipment, but it is actually a diverse ecosystem made up of very different bits of tech.

To give you a better understanding of the marketplace, here is a rundown of the most common examples of CNC gear.

Image Source: Pixabay

Mills

CNC milling is a widely used process across the manufacturing sector for all sorts of projects, and it involves the positioning of a workpiece within a machine which then removes material through the use of drilling and cutting tools. The more axes of movement along which the tool head can operate, the more complex the finished product can be.

As well as being sold brand new, sites like revelationmachinery.com are making used CNC mills available to a wider audience at more affordable prices, while ousting the older, manual milling machinery which might otherwise be in place.

Lathes

In the case of a CNC lathe, it is the work piece that is rotated rather than the tool, which allows not only for materials to be processed quickly, but also means that layers can be removed in a symmetrical fashion.

Aside from speed, the main selling point of CNC machinery is the precision of operation which is afforded to businesses, and this is no more apparent than in the case of CNC lathes. They can do the work of human operators in less time, with fewer mistakes and without any safety risks. Furthermore they can operate for long periods without needing to halt, helping to further boost their appeal as an investment.

Laser cutting

Lasers are a particularly appealing option in the CNC machinery market, since no toolhead needs to physically contact the material which is being worked on. This means that more complex and fragile creations can be brought to life, while also helping to minimize waste and catalyze production processes.

As well as cutting through a variety of different materials, from metal and plastic to ceramics, woods and beyond, CNC laser machinery can also be put to work in a number of other ways. For example, everything from surface etching and ablation to engraving and even cleaning can be carried out thanks to this technology.

Laser equipment is often capable of taking on more than one type of work, and because the laser itself is low-maintenance, running costs can be reduced in the long term.

Plasma cutting

Equivalent to laser cutting but making use of a plasma torch rather than an intense beam of light, this type of CNC equipment is especially well suited to powering through thick plate materials, typically metals.

As you might expect, plasma cutting kit can also be used to weld metals together thanks to the very high temperatures that are achieved during processing. Furthermore because of the automated, precisely controlled nature of their operation, plasma cutting machines are well suited to allowing for very specific areas of material to be cut or welded, without affecting the integrity of the material in the surrounding area, which is clearly desirable.

EDM

An electrical discharge machine (EDM) can be operated through CNC systems and makes use of electrical current to remove material, with a liquid medium used to immerse the work piece and transfer the charge efficiently and safely.

It may sound like an approach which is tricky to manage precisely, but the latest EDM solutions are state of the art in terms of the amount of accuracy and repeatability they offer, making them well worth considering alongside the other CNC machines mentioned so far.

Routers

Similar to CNC mills, although often suited to smaller capacity jobs which need to be completed as quickly as possible, CNC routers can remote material efficiently, whether the work piece in question is made of metals and woods, or even lighter weight counterparts like foams and plastics.

As time has passed, so too have new innovations arrived on the CNC router scene. The latest and greatest examples can come equipped with anywhere from three axes of operation right up to touting a six-axis movement capability. This helps them handle tasks which would previously have been impossible.

So there you have it; CNC machines have come on in leaps and bounds, and cater to the requirements of organizations of all sizes, with cost-effective products for many kinds of manufacturing needs.