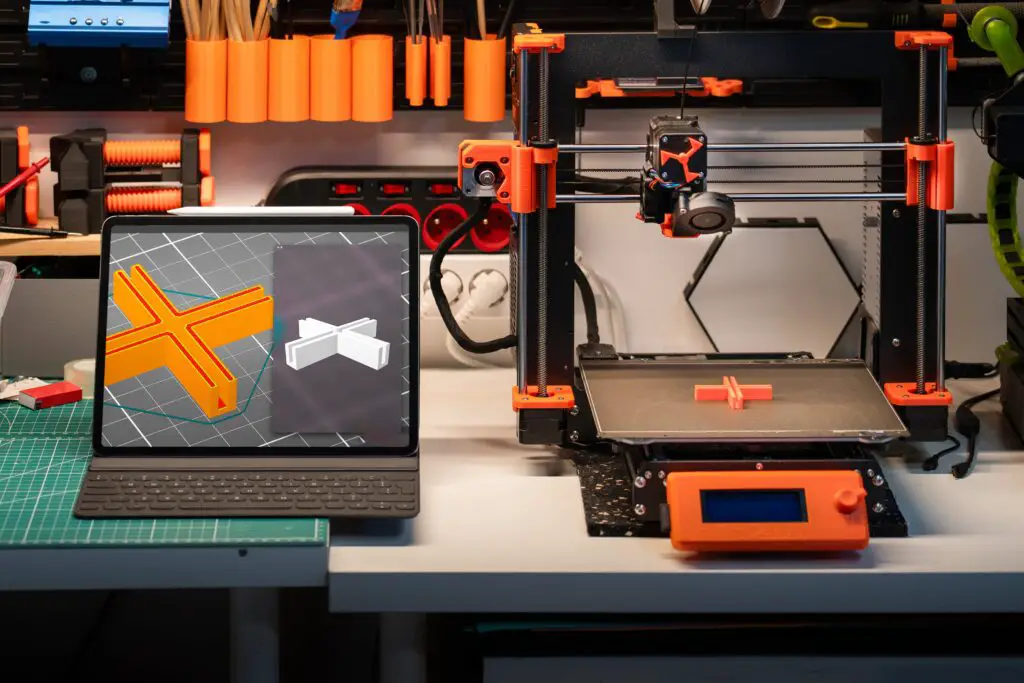

The advent of 3D printing, or additive manufacturing, has heralded a new era in the industrial landscape. Its intricate integration with advanced components like servos and motors has enabled unparalleled precision and customization. This article explores seven transformative impacts of 3D printing in manufacturing, highlighting the synergy between this technology and the sophisticated machinery that drives it.

1. Customization at Scale

One of the most remarkable impacts of 3D printing is its ability to create customized products on a large scale. Servo motors play a crucial role here, providing the precise movement and control needed for the 3D printer’s nozzle or print bed. This precise movement allows for the creation of complex, tailored products that meet specific consumer needs, a feat that was once impossible with traditional manufacturing methods.

2. Rapid Prototyping

3D printing has revolutionized prototyping, largely due to the precise control offered by servo motors. These motors enable quick and accurate movements of the printer head, allowing designers to transform ideas into tangible prototypes swiftly. This rapid prototyping accelerates the design process, allowing for more frequent iterations and a faster transition from concept to production.

3. Complex Geometries and Design Freedom

The ability to print complex geometries is a testament to the precision control offered by servos and motors in 3D printers. They enable the printer to execute intricate patterns and structures, which would be challenging or impossible to create using traditional manufacturing processes. This freedom opens new doors in various industries, from aerospace engineering to medical devices, where complex designs can offer superior performance.

4. On-Demand Manufacturing and Reduced Inventory

3D printing supports on-demand manufacturing, reducing the need for extensive inventory. The precise and efficient operation of 3D printers, driven by high-quality servo motors, allows for the production of parts as and when required. This efficiency not only cuts down on storage costs but also reduces waste, aligning with lean manufacturing principles.

5. Environmental Sustainability

3D printing contributes significantly to environmental sustainability. The precise material placement by servo-driven printers ensures minimal waste during production. Additionally, the ability to produce parts on-site reduces the carbon emissions associated with transporting goods. As 3D printing technology continues to evolve, its role in sustainable manufacturing practices becomes increasingly significant.

6. Democratization of Manufacturing

The democratization of manufacturing, a notable outcome of 3D printing, is partly attributed to the integration of affordable and precise servo motors in consumer-grade printers. These components have made 3D printers more accessible, allowing small businesses and individuals to prototype and produce with a level of precision that was once exclusive to large-scale manufacturers.

7. Integration with Industry 4.0

3D printing’s integration with Industry 4.0 technologies is reshaping manufacturing. Servos and motors in 3D printers are being enhanced with smart sensors and connected to the Internet of Things (IoT), allowing for real-time monitoring and adjustments. This integration leads to smarter, more efficient production processes and paves the way for fully automated and interconnected manufacturing environments.

Conclusion

3D printing is reshaping the manufacturing sector with its flexibility, efficiency, and potential for innovation. The role of servos and other motors in this technology cannot be overstated; they are essential in achieving the precision and control that 3D printing requires. As this technology continues to evolve, its integration with advanced machinery and Industry 4.0 concepts will deepen, further solidifying its position as a transformative force in modern manufacturing. The future of manufacturing with 3D printing promises a shift towards more customized, efficient, and sustainable production methods, fundamentally changing how products are designed, created, and distributed.